High power RPVH120 Power Thick Film Resistors

- Product Description

-

RPVH120 Power Thick Film Resistors

Scope:

This specification specifies the general characteristics and requirements for RPVH 120 power type thick film resistors.

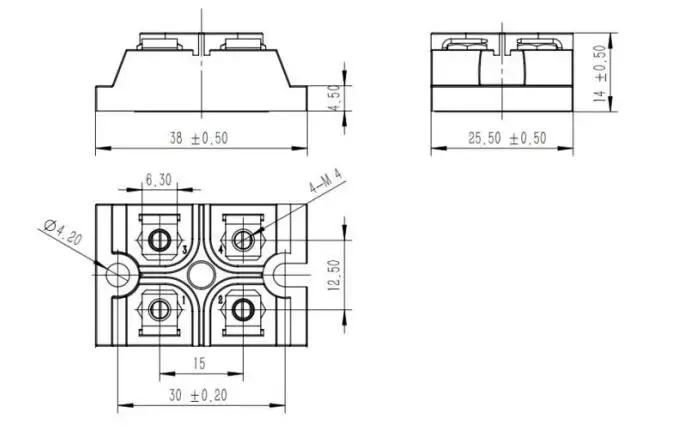

Dimensions:Size name:mm Package type: SOT-227

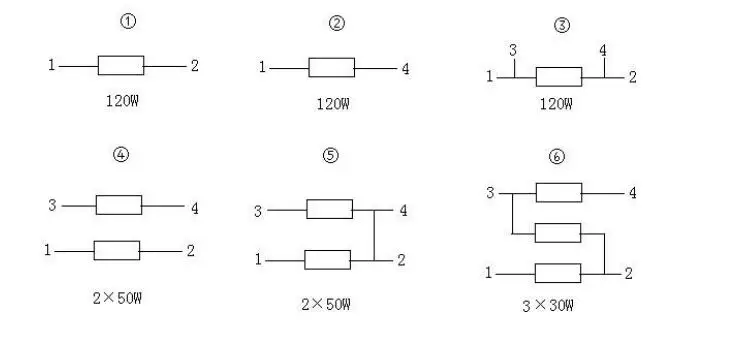

Resistor structure:

Reference Standard:

GB/T 5729-2003 Fixed Resistors for Electronic Equipment Part 1: General Specification

GB/T 2828.1-2012 Batch-by-batch inspection technical sampling procedure and sampling table GB/T 2691-2016 Marking method of resistors and capacitors

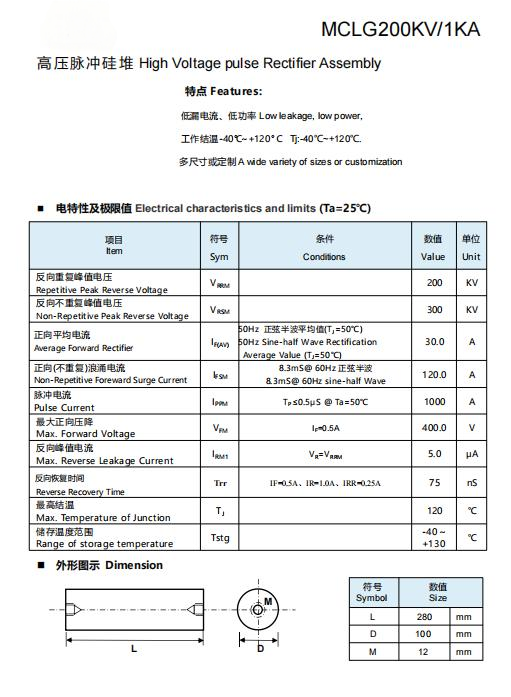

The main technical parameters:Rated power

When the base plate temperature is ≤70℃, the rated power is 120W

Resistance /Ω

1--1M

Allowable deviation

±5%

Temperature Coefficient

±250ppm/℃(25-85℃)

Maximum working voltage

1500V DC

Insulation withstand voltage

5KV DC 1min

Distributed capacitance

<45pF

Insulation resistance

>10GΩ

Range of working temperature

-55℃-+155℃

Main inspection items, inspection methods and performance requirements:

project

Test conditions

Performance requirement

Terminal strength

Soft lead pull: 10N, stud type 1.0N.m torque

ΔR≤±(1%R+0.05Ω)

high frequency vibration

Frequency 10~500Hz, 10g, 6h

ΔR≤±(1%R+0.05Ω)

overload

Apply 1.5 times the rated power voltage for

10s

ΔR≤±(0.4%R+0.1Ω)

Room temperature durability

The rated power load is 1000 h, and the

bottom plate temperature is less than 70 ℃

ΔR≤±(5%R+0.05Ω)

Radiator installation method and requirements

The resistor is installed on the radiator with 2 M4 screws, and the installation torque is less than or equal to 1.3N.m (to ensure the use of power and excellent heat dissipation);

The contact surface must be cleaned;

The flatness of the radiator is: 0.05mm-0.1mm (within the range of 100mm); The roughness of the radiator must be 6.3um;

To improve thermal conductivity, contact surfaces (alumina, heat sinks) should be coated with silicone grease.

Product Inquiry

We will contact you within one working day. Please pay attention to your email.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.